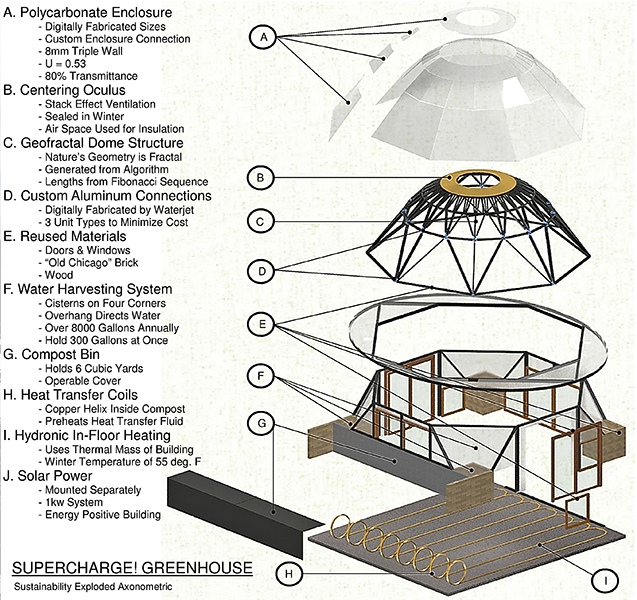

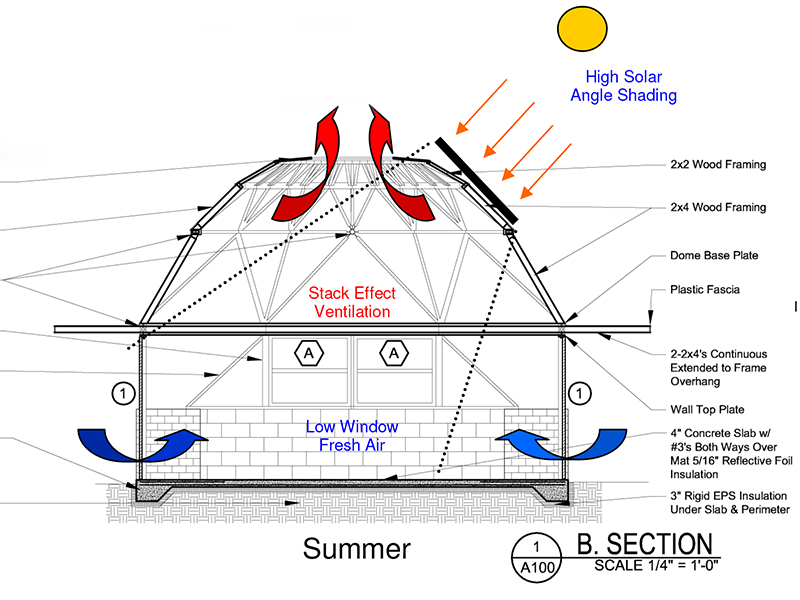

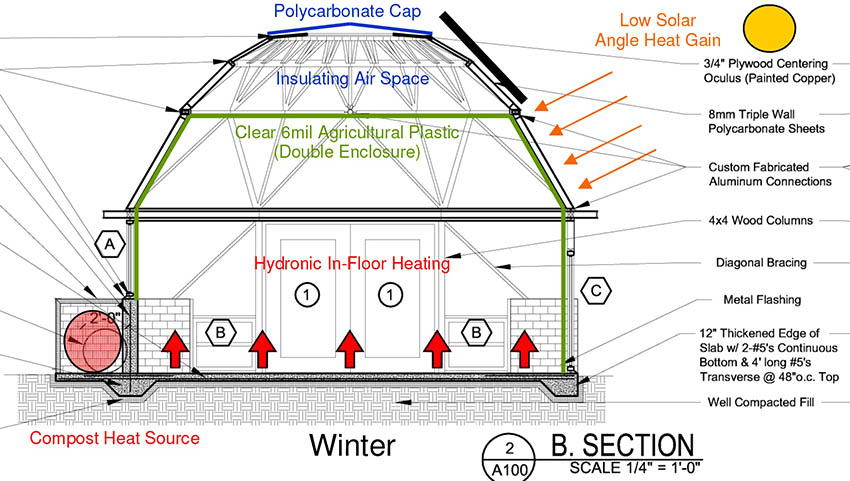

- The Geometry of Nature very often combines fractal geometry and the Fibonacci sequence as the Geofractal Greenhouse was designed. This timeless principle was a fundamental inspiration for the design of the dome structure.

- The building was modeled using Autodesk 3Dsmax software that accurately calculated the complex angular connections required for the geofractal dome. Digital files were supplied to the fabricator and the aluminum was cut with a CNC water jet machine and welded together. Digital fabrication was also used to model the size of the polycarbonate panels and the aluminum connection strips that fasten them to the structure. The strips were cut with a CNC laser machine and bent to the correct angles for each segment of the dome. The polycarbonate panels “flex” to the curvature of the structure and exert pressure each other where they are shingled for water drainage.

- The Life Cycle Assessment (LCA) was performed using the International Standards Organization 14040 process. LCA’s are calculated for both typical materials and for the reused and recycled materials used in construction. It uses the University of Bath Inventory of Carbon and Energy (ICE) database for the Embodied Energy and Carbon Dioxide values. It also uses EPA databases to calculate the transportation and construction processes. The use of reused and recycled materials reduced the Carbon Dioxide by 27% and the Embodied Energy by 13%.

- The construction of the Supercharge Greenhouse was only possible because of the architect led design / build procurement method. An experimental building with geofractal dome, digital fabrication and compost heating system would have been cost prohibitive with a traditional delivery process.

Geofractal Greenhouse

-

Location

Miami

-

Services

Design, Enginering & Construction